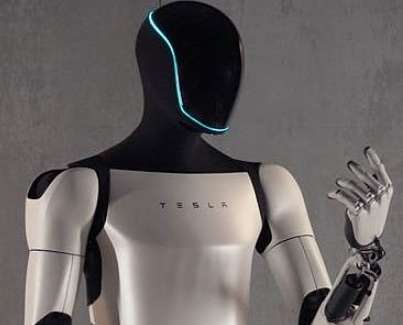

Tesla Reportedly Pauses Optimus Robot Production Amid Design Overhaul

It looks like Musk is having another problem.Information from Chinese supply chain sources indicates that Tesla is currently focused on adjusting the hardware and software details of its humanoid robo

It looks like Musk is having another problem.

Information from Chinese supply chain sources indicates that Tesla is currently focused on adjusting the hardware and software details of its humanoid robot, Optimus, and suspended parts procurement for Optimus about half a month ago.

Two supplier sources said Tesla has not explicitly stated it will reduce robot parts orders but will wait until the Optimus design adjustments are completed before finalizing a new mass production plan and resuming procurement. The adjustments may take two months. Musk recently stated on social media that the new version of Optimus has seen significant improvements over the second-generation Optimus unveiled in 2023 and now includes voice interaction powered by Grok.

As of the end of May this year, Tesla had procured enough parts to produce 1,200 Optimus units and had manufactured close to 1,000. Musk had previously pledged to produce 5,000 units this year. Both sources mentioned believe that with the suspension of parts procurement, this target is now largely unattainable.

The adjustments began in early June when Milan Kovac, the original head of Tesla's Optimus project, left the company. One supplier source said Ashok Elluswamy, Tesla's AI software VP, took over the Optimus project and aims to refine the design before pushing forward with mass production. Elluswamy previously led the development of Tesla's Full Self-Driving (FSD) software and has been with Tesla for 11 years.

Apart from the Cybertruck, Tesla has not launched a new car in six years, only releasing minor facelifts. As Musk's relationship with the current U.S. president deteriorated, he re-emerged at Tesla's offices. Following the timely launch of the Robotaxi in Texas last month, Tesla is also advancing the timeline for its refreshed models. According to sources, a smaller, revamped Model Y will be delivered in the U.S. by the end of this year, while the seven-seat Model Y will debut simultaneously in China and the U.S. in October.

Tesla's executive team has also seen frequent changes. Omid Afshar, VP of North American and European sales and manufacturing, left at the end of June. His responsibilities have since been divided between Musk and Tom Zhu. In the first half of this year, five other Tesla executives also departed.

After the senior management shake-up in April last year, Tesla's SVP (core leadership) team was left with only Musk and Tom Zhu. Tesla has yet to appoint any new SVPs.

According to Tesla's feedback to suppliers, Optimus still faces hardware challenges, including overheating in some joint motors, low load capacity in dexterous hands, short lifespan of transmission components, and limited battery life. Tesla is currently evaluating samples from multiple dexterous hand suppliers, testing at least three different technical approaches. On the software side, Tesla may use more synthetic data to train the robot model, improving Optimus' autonomous operation capabilities and success rate in performing complex tasks.

At the "We, Robot" event on October 10 last year, Tesla showcased several Optimus units dancing, pouring wine, and interacting with humans. However, most of the actions performed by Optimus at the time were remotely controlled by engineers.

A Tesla insider revealed that Optimus is currently only used for moving batteries in Tesla's battery workshops, with efficiency less than half that of human workers, and has not yet been deployed for more complex tasks like car assembly.

According to Musk's plan, Tesla will produce 50,000 Optimus units next year and begin sales; by 2027, Optimus will travel to Mars aboard SpaceX's Starship; and by 2029, annual Optimus production will exceed 500,000 units. This is already a scaled-back version of Musk's original vision—he initially aimed to ramp up Optimus production to 1 million units annually by 2027. This may not be a rigorous business plan.

Tesla has spent three years developing robot hardware with hundreds of supply chain partners, establishing a complete humanoid robot supply chain. The Optimus R&D team exceeded 400 people by the end of last year. Based on a per-unit cost of $60,000, Tesla originally planned to spend over $300 million on parts this year alone.

Prior to this news, Tesla's stock had already closed down 5.34% on Tuesday. Multiple investment banks lowered their Q2 delivery expectations, citing weak demand in Europe and China. Meanwhile, Musk's escalating feud with Trump on social media has raised investor concerns about potential policy retaliation.

Therefore, people who are familiar with the matter said Tesla may unveil the third-generation Optimus at this year's shareholder meeting. Musk needs to prove that the new product justifies continued investment from Tesla shareholders and hundreds of supply chain partners, reversing the negative market sentiment.

Disclaimer: The views in this article are from the original Creator and do not represent the views or position of Hawk Insight. The content of the article is for reference, communication and learning only, and does not constitute investment advice. If it involves copyright issues, please contact us for deletion.